1. Scope of application

1.1 It is suitable for low-temperature water transfer printing of various substrates such as bicycle frames, helmets, rackets and other sports equipment, and can be peeled off;

1.2 It is suitable for various weather environments and various curved surfaces, with wide adaptability.

2. Characters

2.1 Appearance: colorless transparent viscous resin solution;

2.2 Main ingredients: methacrylic polymer resin;

2.3 Solid content: 44.5%±1.5% (weight percent);

2.4 Viscosity: 7500± 2500 mPa.s (rotational viscometer, 6rpm, 25°C)

4000± 1000 mPa.s (rotational viscometer, 60rpm, 25°C).

3. Features

3.1 Excellent printability, smooth surface, no flying ink, no stringing;

3.2 It has high strength, toughness and suitable flexibility, and the process tolerance is large, suitable for surface transfer of various areas;

3.3 The film can be dried naturally or after drying, which is suitable for assembly line operation and improves production efficiency;

3.4 Good peelability, it is not easy to get ink when tearing off the film after reposting;

3.5 The printed flower paper has a long shelf life and is not easy to be brittle.

4. Printing and reposting process

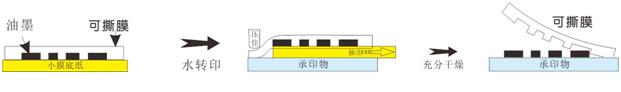

4.1 Print ink on the water transfer backing paper, and finally print isolation varnish on the pattern part; after it is completely dry, use a 60-80 mesh (inch) polyester or nylon screen to print a tearable film with a screen thickness of 15- 25μm is the best;

4.2 Soak the decal paper that has been printed on the tear-off film and completely dried in water for 2-3 minutes;

4.3 Put the soaked transfer paper on the substrate, press the side of the tear-off film with your fingers, and remove the backing paper from between the film layer and the substrate;

4.4 Use soft squeegee to drive away the air bubbles between the tearable film and the substrate, so that the film layer and the substrate can be closely attached;

4.5 After the tear-off film on the substrate is dried naturally or below 120°C, tear off the tear-off film, and then bake according to the material of the substrate;

4.6 Add YR-6900 special softener when it is necessary to improve the softness of the YR-6900 tearable film for posting extremely irregular large curved surfaces or for use in severe cold weather;

4.7 Under normal circumstances, the tearable film does not need to be diluted, but according to the situation, a special solvent for the tearable film can be added appropriately;

4.8 For screen cleaning, it is recommended to use a special solvent for tear-off film or general solvent.

5. Matters needing attention

5.1 After printing the isolation varnish, if the surface is not fully dry and the tear-off film is printed, the tear-off film will not be easy to peel off when reposting, so the ink layer must be completely dry before printing the tear-off film;

5.2 After the printed decal is pasted on the substrate, it needs to be fully dried before tearing off the tear-off film;

5.3 The use of the above process needs to go through sufficient production experiment demonstration to determine the best printing, drying and baking methods;

5.4 The printed flower paper should not be stored for a long time, it is recommended to use it up within one month;

5.5 The solvent used is flammable, please keep away from fire sources;

5.6 In order to avoid deterioration of the operating environment caused by organic solvents, please fully ventilate;

5.7 Please store the leftovers after use in a cool and dark place.

Copyright DENBISHI Intelligent Technology (Kunshan) Co., Ltd.