1. Scope of application

It is suitable for pattern water transfer printing of irregular surface substrates such as ABS and other plastic materials. Widely used in motorcycle helmets, fishing rods, golf clubs, rackets and other sporting goods.

2. Product Features

2.1 Single-liquid low-temperature baking type;

2.2 Good adhesion on plastic materials;

2.3 Environmental protection, in line with EU ROHS directive, EN-71 PART3 standard.

3. Product properties

3.1 Test conditions: This test is transferred to the ABS material with black ink, and it is forced to dry at 90°C for 30 minutes;

3.2 Test method: After drying, test the sample after standing for 2 hours;

3.3 Special Note: The above test results are based on our company's environment, not guaranteed values, and are for reference only.

4. Printing and transfer printing process

4.1 Printing

4.1.1 Use a 200-350-mesh screen to print 60 series inks on the small film water transfer backing paper, dry naturally at room temperature for more than 4 hours, and do not heat and dry;

4.1.2 After the ink is completely dry, it is recommended to use Tianling YR series tear-off film, 60-80 mesh screen plate, film thickness 15-25μm for printing;

4.1.3 Please use TT series special thinner, and the addition ratio is 1-10%. It is recommended to use TS-300 special cleaning agent for screen cleaning.

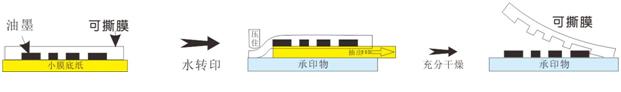

4.2 Transfer printing

4.2.1 Soak the decal paper that has been printed on the tear-off film and completely dried in water for 2 to 3 minutes;

4.2.2 Put the soaked flower paper on the substrate, press one side of the tearable film with your fingers, remove the backing paper from between the tearable film and the substrate, and then use a soft squeegee to seal the tearable film Remove the air bubbles between the film and the substrate, so that the film layer and the substrate can be closely bonded;

4.2.3 After the transferred substrate is fully dried at room temperature for more than 2 hours, the tear-off film is torn off, and then the substrate is baked. If you use a non-tear film, you don't need to tear it off and bake it directly. Baking conditions: 90℃× 30 minutes.

5. Matters needing attention

5.1 Due to the difference in substrate material and working environment, the reference heating temperature and time will change, please fully test before batch use;

5.2 Please be sure to use TT series special thinner when diluting, and it cannot be mixed with other inks or solvents;

5.3 If higher adhesion is required, the adhesion promoter (DA-001) provided by our company can be used;

5.4 When using this product, please be sure to obtain the specified MSDS, read it carefully and understand the user's responsibilities before using it.

6. Save

Please keep away from fire sources, and keep sealed in a dark, cool and ventilated place.

7. Shelf life

One year from the date of manufacture. After opening, it is recommended to use as soon as possible.

Copyright DENBISHI Intelligent Technology (Kunshan) Co., Ltd.